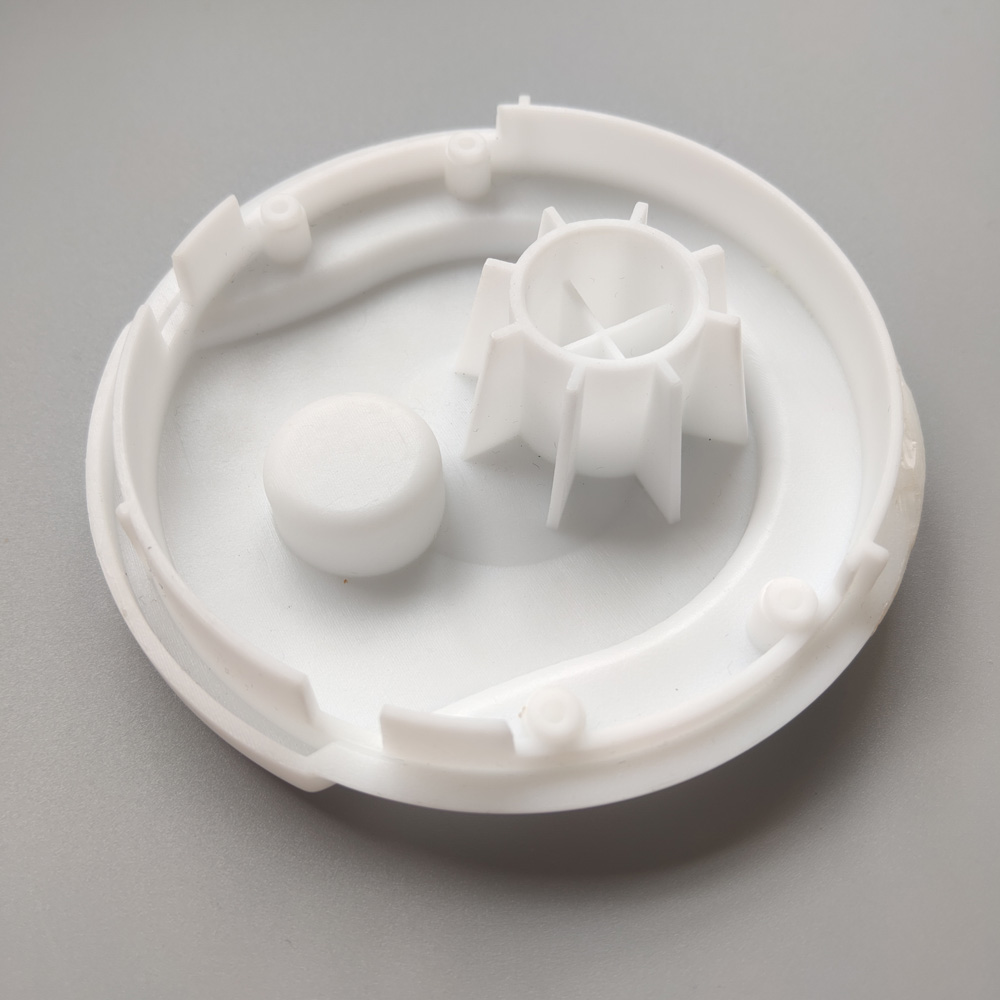

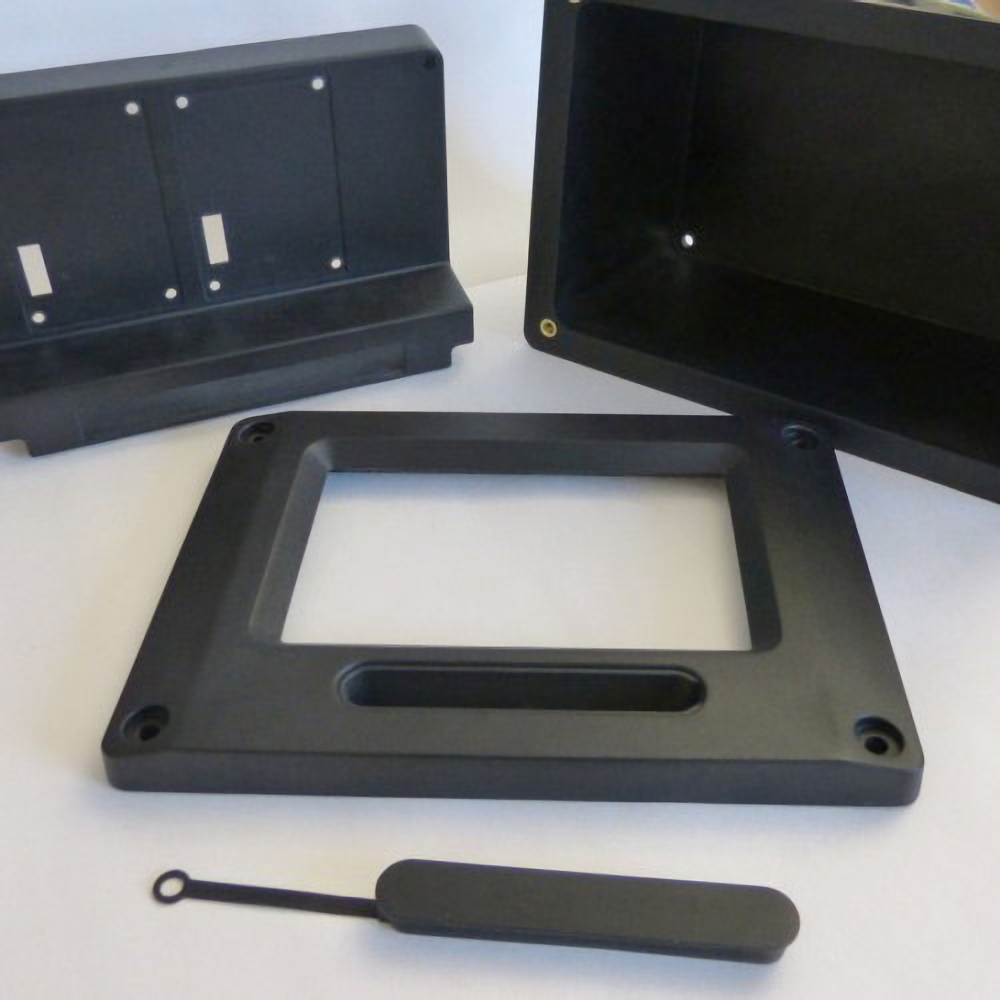

Vacuum casting provides end-use, rigid plastic parts or rubber parts with production-level quality. Built without expensive and time-consuming hard tooling, vacuum casting process uses a 3D printed master pattern and silicone molds to deliver high-quality, short-run parts up to 30” long. The finished dimensions of vacuum cast parts depend on the accuracy of the master model, part geometry, and casting material. In general, a shrinkage rate of + 0.15% is expected. Cast urethane parts are frequently used when color, surface quality, and toughness are required. vacuum molding is a perfect alternative for insert molding or over molding in low volumes with diverse material choices. vacuum casting can also be used for bridge-tooling between a 3D printed rapid prototype and an injection molding with a balance of quality, cost, and time. Vacuum cast parts can also be clear, color-matched, painted (including EMI shielding), have installed inserts, and even custom finished.