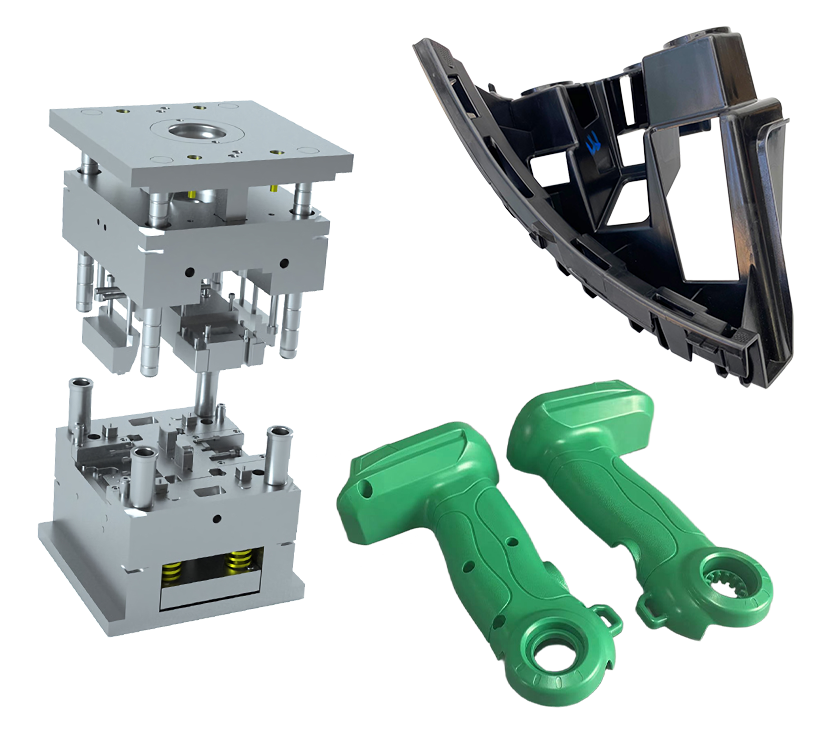

Injection molding is the most cost-effective way to make a plastic part at scale. The injection molding process involves injecting molten plastic into a mold tool, then ejecting the solidified part.

This process quickly repeats hundreds or thousands of times, amortizing the cost of the mold tool and driving down the cost of each unit to a few dollars or less. Since the injection molding process uses the same mold tool for each part, it offers consistent quality across every part.

Injection molding also has the highest variety of materials, colors, cosmetics, polishes, and surface textures when compared to CNC machining or even 3D printing.